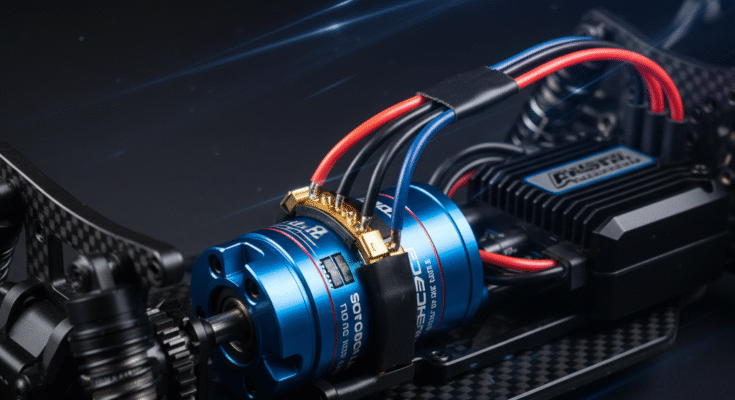

The world of high-performance RC (Remote Control) vehicles—be it race buggies, drift cars, or demanding crawlers—is a relentless pursuit of efficiency, reliability, and precision. Every component, from the battery to the wheel, is scrutinized for maximum performance. In the brushless motor system, the link between the Electronic Speed Controller (ESC) and the motor is the conduit for immense power, and it often becomes an unexpected bottleneck. Sensored Motor Solder Tab Extensions Kit

While many motors feature standard solder tabs, modern chassis designs and the quest for perfectly clean wiring often make direct soldering awkward, stressing the connection points and sacrificing efficiency. This is where the Sensored Motor Solder Tab Extensions Kit enters the scene, offering a clean, robust, and professional solution that every serious RC enthusiast should consider.

This comprehensive guide delves into what these kits are, why they are essential for competitive racing and dedicated hobbyists, and how they dramatically improve your vehicle’s wiring, power delivery, and overall reliability.

Understanding the Challenge: The Limits of Standard Tabs

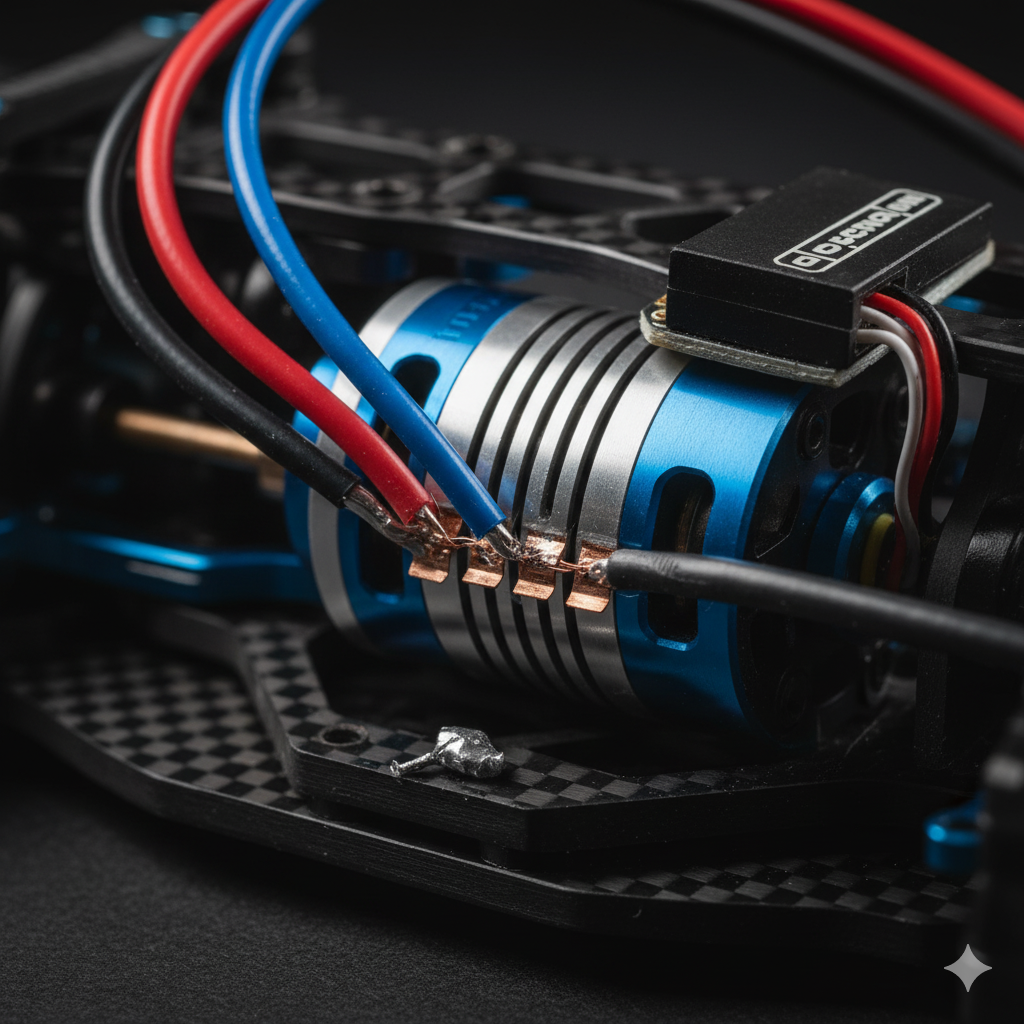

In a sensored brushless motor system, there are two sets of connections: the three large phase wires (A, B, C) that carry the high-amperage power from the ESC, and a small sensor cable that communicates the motor’s exact rotor position back to the ESC for smooth, low-speed operation.

The standard motor design presents several issues, especially in tight chassis layouts:

- Awkward Angles: Motor tabs are often small and positioned in a way that forces the power wires to bend sharply as soon as they are soldered, especially when trying to maintain a neat, low-profile wire path.

- Strain Relief Deficiency: A sharp bend immediately adjacent to a solder joint creates a severe stress riser. Constant vibration, chassis flex, and even temperature changes can cause the solder joint to crack or the thin motor tab to break completely (Result 1.2), leading to a catastrophic power failure mid-run.

- Heat Exposure: Repeated soldering to the original motor tabs, necessary when swapping motors or ESCs, subjects the internal motor windings to excessive heat, risking permanent damage to the insulation (Result 1.4).

- Aesthetics and Clearance: In high-level racing, neat wiring is crucial for diagnostics, maintenance, and meeting technical inspection standards. Small, standard tabs make achieving a “factory” look difficult and can lead to wires rubbing against the chassis or battery.

The Sensored Motor Solder Tab Extensions Kit solves all these problems by creating a dedicated, robust, and optimized interface.

What Exactly is a Solder Tab Extensions Kit?

A typical high-quality kit consists of three main components, usually made of robust, high-purity copper or brass, sometimes coated in a highly conductive finish like gold:

- Extended Power Tabs (3 pieces): These are rigid, often large metal strips or small circuit boards designed to bolt directly onto the existing motor phase tabs (A, B, C). They provide a much larger, perfectly flat, and securely anchored surface area for soldering the thick gauge ESC wires.

- Mounting Hardware: High-tensile strength screws are included to mechanically fasten the new extension tabs to the motor. This mechanical connection is the key to strain relief and stability.

- Insulation/Support: The kit may include custom-cut heat shrink tubing, plastic support shrouds, or a carbon fiber plate that helps protect the exposed solder joints and maintain the clean, predetermined wire angle.

These kits are a mandatory upgrade in high-end RC racing classes where milliseconds matter and DNF (Did Not Finish) is unacceptable.

The Crucial Benefits of the Upgrade

The decision to install a solder tab extension kit moves beyond mere aesthetics and directly impacts performance and reliability.

1. Superior Strain Relief and Durability

This is the single most important benefit. By bolting the extension tab to the motor body,

the structural load of the heavy ESC wires is transferred mechanically to the rigid motor casing,

not to the delicate, small solder joints of the internal windings.Sensored Motor Solder Tab Extensions Kit

- Prevents Breaks: The risk of breaking off a motor tab—

- a common failure point in high-vibration applications—is virtually eliminated (Result 1.2).

- Isolates Vibration: The extension acts as a buffer,

- ensuring that movement and vibration are absorbed by the extended tab and the wire insulation,

- protecting the critical, permanent solder point on the motor itself.

2. Optimized Current Flow and Efficiency

Bigger is often better when it comes to high-amperage connections. The extension tabs offer a large, flat surface that ensures a flawless, low-resistance solder joint.Sensored Motor Solder Tab Extensions Kit

- Maximum Conductivity: A clean, large-surface solder connection minimizes electrical resistance (). Lower resistance means less power is wasted as heat,

- leading to slightly cooler motor and ESC temperatures and ensuring the maximum possible current (amperage) reaches the motor windings.

- Tidy Wiring, Better Airflow: The ability to pre-determine the exit angle of the wires allows for ultra-neat routing, keeping them away from moving parts and ensuring they don’t block airflow to the motor or ESC fan, which is crucial for temperature management.

3. Effortless Maintenance and Swapping

For racers who frequently swap motors or ESCs between different classes or tracks, the extension kit is a game-changer.

- Reusable Connection Point: The main ESC wires are soldered once to the extension tabs. When you need to replace the motor, you simply unscrew the extension tabs and move them to the new motor, or you can use bullet connectors to easily disconnect the ESC wires (Result 1.3, 4.2). This saves time and protects both the ESC and motor wires from repeated cutting and re-stripping.

- Heat Protection: Repeatedly heating the tiny original motor tabs significantly risks damage. With extensions, you solder once for a secure, permanent connection to the extension, protecting the motor’s core windings from future thermal stress.

4. Professional and Race-Legal Aesthetics

In competitive RC, presentation matters. A clean wire job is a sign of a meticulous racer, and extension kits deliver the goods:

- Symmetry and Order: They provide a uniform base for the three phase wires, making it simple to achieve the straight.

- perfectly angled wiring often seen on pro-level builds.

- Clearance: They allow the wires to exit the motor in a controlled manner.

- preventing clearance issues with the vehicle’s driveshaft, slipper clutch, or battery packs.

Installation Guide: A Smooth Soldering Job

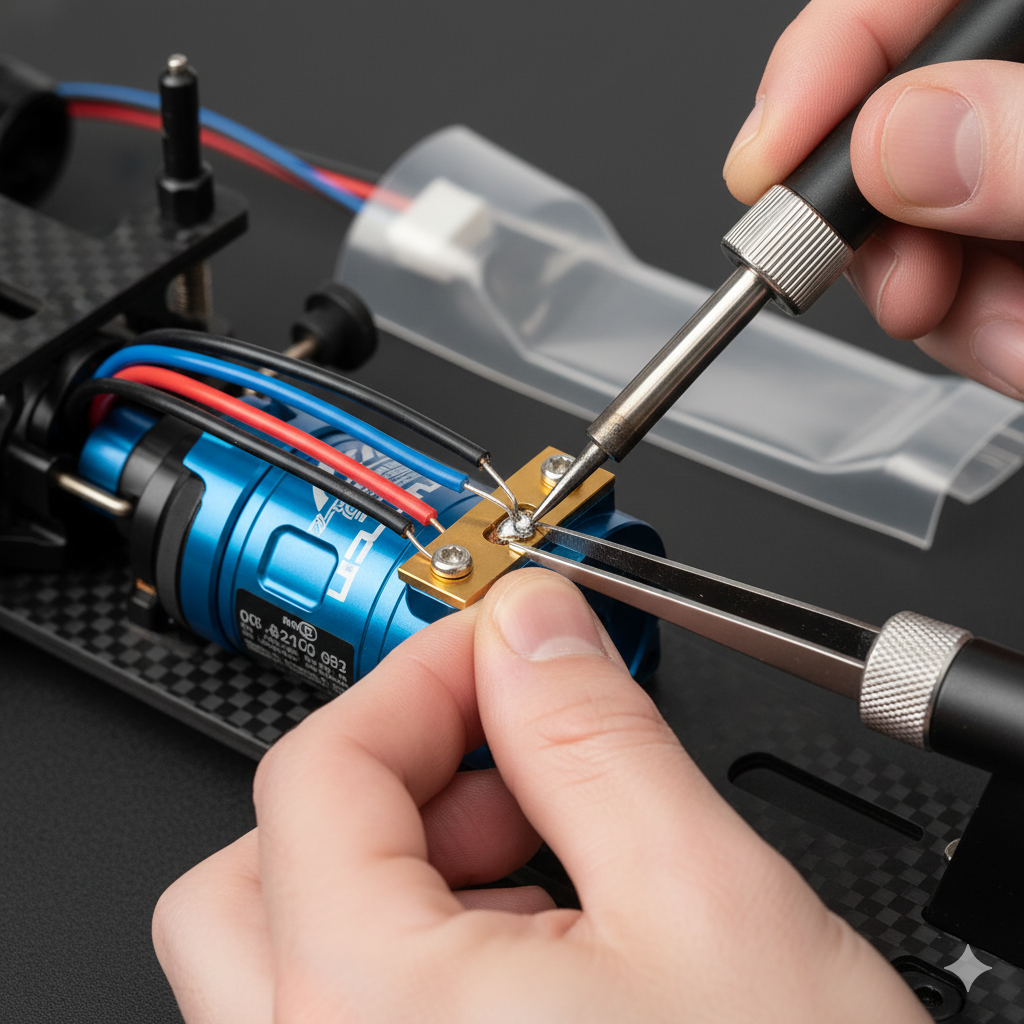

Installing a motor tab extension kit is straightforward, but requires precision soldering skills. Here’s a basic overview of the process:

- Preparation is Key:

- Tools: Ensure you have a high-wattage soldering iron (60W minimum, 80W+ preferred for quick, clean work), quality rosin-core solder, flux paste, and a “helping hands” tool.

- Tinning: Clean the contact surfaces of the motor’s existing tabs and the new extension tabs. Apply a small amount of flux and then “tin” them by coating them lightly with molten solder.

- Mounting the Extensions:

- Carefully align the extension tabs with the motor’s existing tabs (A, B, C) and secure them using the provided screws. Ensure a tight, mechanical connection. The goal here is physical stability.

- Soldering the Extensions to the Motor:

- With the iron heated, quickly touch the tip to the junction of the two tinned tabs and feed a small amount of solder.

- Because the tabs are physically joined, the solder will flow rapidly,

- creating a seamless, low-resistance electrical and physical bridge. Work quickly to minimize heat transfer to the motor’s internal components.

- Connecting the ESC Wires:

- Strip and tin the three ESC power wires (typically 12AWG or 13AWG).

- Decide on the perfect exit angle for your wires.

- Flux the surface of the extension tabs again.

- Solder each tinned wire to its respective extension tab, using a powerful iron to make the joint in just 1-2 seconds.

- Final Touches:

- Apply the supplied heat shrink or protective covering to insulate the new, large solder joints.

- Secure the wires to the chassis using cable ties to provide final strain relief, ensuring there is a small, flexible loop of wire right after the motor to absorb movement.Sensored Motor Solder Tab Extensions Kit

Conclusion: The Professional Edge

In the high-stakes world of RC, the Sensored Motor Solder Tab Extensions Kit is far more than a luxury; it’s a performance-enhancing necessity.

It’s an investment in the long-term health of your expensive motor/ESC system. ensuring that the connection responsible for transferring peak power is as robust and efficient as possible.By providing perfect strain relief, maximizing current flow, and simplifying the maintenance cycle, these kits allow racers and enthusiasts to focus on tuning and driving,rather than troubleshooting loose solder joints. If you are serious about clean wiring, peak performance, and absolute reliability, upgrading to a solder tab extension kit is the next logical step in optimizing your RC power system. It’s the professional touch that guarantees your vehicle will perform at its absolute best, lap after lap.

Click Here For More Information