The vast and varied universe of scale modeling includes a subset of the hobby that offers a unique, tangible, and often weighty satisfaction: the metal model kit. Plastic cement fumes mingle with the precise scent of acrylic paints in this world. Unlike their ubiquitous plastic cousins, metal kits challenge the builder with specific material properties: the cool resilience of steel, the satisfying heft of die-cast parts, and the fiddly, minute detail of photo-etched brass. This corner of the craft demands patience, precision, and a different kind of respect for the material. The finished product rewards the dedicated builder. It functions as much as an industrial miniature as it does a model.Metal Model Kits

The journey of metal models evolved from simple educational toys into intricate, collector-grade masterpieces. To truly appreciate this niche, we must delve into its history. We also need to explore the different types of metal kits available today and understand the unique joy and challenge they bring to the workbench.

From Meccano to Metal Earth: A History Forged in Steel

The concept of a buildable metal toy is not new. Its roots stretch back to the late 19th and early 20th centuries. The true precursor to the modern metal construction set is arguably Meccano. Frank Hornby patented it in 1901 in the United Kingdom. Originally called “Mechanics Made Easy,” this system of reusable metal strips, plates, nuts, and bolts was revolutionary. It allowed children and engineers alike to construct functional, dynamic models of cranes, bridges, and vehicles.

As the hobby evolved in the mid-20th century, plastic began to dominate the scene. It offered ease of molding, low cost, and the ability to capture complex organic shapes. Metal, however, never truly vanished. The rise of companies like Aluminum Model Toys (AMT) in the post-war American market shows this. They initially used cast aluminum for their promotional car models before shifting to plastic for mass production. This die-cast legacy, where molten metal is forced into a mold, lives on today. I

The most significant modern revolution came with the advent of photo-etched metal models in the 21st century. The technique uses a photo-resist and chemical etching to create incredibly thin, highly detailed metal sheets, often stainless steel or brass. This changed the game. Invented in China in the mid-2000s, brands like Metal Earth and Piececool popularized this technology globally.

The Two Titans of Metal Model Kits

Two distinct styles dominate the modern landscape of metal model kits. Each offers a fundamentally different building experience:

1. Photo-Etched (PE) Kits: The Precision Puzzle

What they are: These kits consist of one or more flat sheets of metal with precisely cut and etched parts. The builder must snip out the parts. Then they fold, roll, and twist small tabs through corresponding slots to join them. You essentially build a 3D object from 2D components. Builders typically require no glue or solder, though it is sometimes recommended for stability or permanence.

The Experience:

- Challenge: Extreme precision and fine motor skills are essential. The tiny tabs can snap easily if you over-bend them. Shaping delicate curves requires specialized miniature tools, such as needle-nose pliers, tweezers, and cylindrical objects for bending.

- The Reward: The completed model is often a surprisingly intricate and airy sculpture with a brilliant, industrial metallic sheen. The sheer level of detail that photo-etching makes possible—down to tiny railings, mesh, and rivets—is often superior to what injection-molded plastic achieves. Themes range from world-famous architecture (Eiffel Tower, Notre Dame) and massive ships to licensed pop culture icons (Star Wars, Marvel).

2. Die-Cast/Hybrid Kits: The Weight of Quality

What they are: These kits often appear in the high-end mecha and vehicle modeling space. They primarily use metal parts (die-cast zinc alloy or aluminum) for the internal frame, chassis, or critical components where weight and stability are paramount. The outer armor and highly detailed pieces may still be plastic.

The Experience:

- Challenge: The core construction might follow traditional plastic kit methods (snap-fit or cement). However, working with the die-cast frame requires different techniques. The metal pieces provide an immensely satisfying heft to the finished product.

- The Reward: Brands like Bandai’s Metal Build (these showcase the metal’s appeal, though often pre-assembled) or specialized third-party inner-frame kits for Gunpla leverage metal. They create action figures or models with a superb center of gravity, firm joints that hold a pose, and a truly premium feel. The finished model stands tall and imposing. You hold a genuine metal artifact.

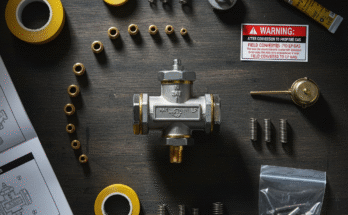

Essential Tools for the Metal Modeler

A plastic kit might only require a hobby knife and cutters. The metal model, however, demands a specific arsenal tailored to its material:

- High-Quality Nippers/Cutters: You need these to cleanly separate PE parts from the metal sheet without warping the delicate piece.

- Fine-Tip Tweezers: These are non-negotiable. Builders use them to hold, bend, and twist the microscopic joining tabs. Look for high-precision, fine-point tweezers.

- Miniature Needle-Nose Pliers: They are crucial for forming sharp 90-degree bends and holding larger pieces.

- Bending and Shaping Tools: Specialized tools like a PE Bending Tool (a small vice for making perfect folds) are necessary. You also need a collection of variously sized cylindrical objects (drill bits, pens, dowels) to roll the metal into pipes, domes, or curves.

- Adhesive (Optional but Recommended): Metal Earth kits are glueless, but a tiny dab of super glue (CA glue) is often a lifeline. Use it for pieces that refuse to hold or for a tab that accidentally snaps off. A quick-setting epoxy works well for heavier die-cast joints.

The Zen of Metal Model Building

The appeal of a metal model kit isn’t just the finished display piece; the process itself holds profound satisfaction. Building with metal is a meditative and deeply satisfying endeavor. It contrasts sharply with the quick, mass-produced feel of other hobbies.

- Patience is a Virtue: The scale of PE parts can be eye-straining. The work requires the builder to slow down, breathe, and focus on the immediate task. It forces a measured pace that feels therapeutic in a fast-paced world.

- The Tactile Satisfaction: The clean snip on a steel sheet, the feel of a perfectly rolled curve, the click of a tab locking into place—these small, simple joys are unique to the medium. The metal, unlike plastic, gives little allowance for error. A bend is final; you cannot melt or mold it back. This instills a sharp sense of reverence for each action.

- A Timeless Display: The finished metal model possesses an inherent permanence. It doesn’t require painting (unless desired). The natural finish—be it the raw silver of stainless steel or the rich colors of treated brass—gives it an authentic, mechanical look. It looks like a miniature artifact retrieved from an industrial blueprint.

Conclusion

Metal model kits represent the intersection of modern manufacturing precision and old-world craftsmanship. They are not merely models; they are intricate, industrial puzzles. They test the builder’s resolve and reward them with a miniature sculpture of undeniable quality and satisfying weight. The tradition of building with metal offers a unique and enduring pleasure, from the click-clack of Meccano to the delicate folding of a Piececool cathedral.