The feeling is immediate: a soft, spongy brake pedal, a warning light, or worse—a visible puddle of fluid beneath your vehicle. When your car’s braking system signals distress, it’s a non-negotiable safety emergency, often caused by a failing brake line. Brake Line Repair Kit

For the confident DIYer, a brake line repair kit offers a faster, more affordable solution than a professional replacement. But automotive brakes are a zero-tolerance system. Is attempting this critical repair truly safe, and what technical challenges does it involve?

This guide will demystify brake line repair kits, explore the signs of a failing line, detail the specific tools and materials required for a safe repair, and provide a clear framework for deciding when to tackle the job yourself versus calling a professional mechanic.

The Unsung Hero: How Your Brake Lines Keep You Safe

Your vehicle’s brakes operate on a hydraulic system. Pressing the pedal activates the master cylinder, which pressurizes the brake fluid. The brake lines—narrow, rigid, and flexible tubes—transmit this high-pressure fluid to the calipers or wheel cylinders at each wheel. This pressure translates your foot effort into the clamping force required to stop the vehicle. If a brake line is compromised by a leak or corrosion, that vital hydraulic pressure is lost, leading to reduced braking power, a spongy pedal, or a catastrophic loss of stopping ability.

Critical Red Flags: Signs of a Failing Brake Line

Early detection of a brake line problem is crucial for safety. Be vigilant for these immediate warning signs:

- Leaking Brake Fluid: The most obvious indicator. Brake fluid is clear-to-yellowish when new and darkens with age. Check for puddles under the car, especially near the wheels or frame.

- Soft or Spongy Pedal: If the brake pedal sinks easily to the floor or requires repeated pumping, it signals a major loss of hydraulic pressure due to a leak.

- Illuminated Brake Warning Light: The dashboard light often triggers when the brake fluid reservoir level drops significantly, which almost always points to a leak.

- Visible Corrosion: During inspection, look for heavy rust, pitting, or flaking on the metal lines, particularly in areas exposed to road salt. Check rubber hoses for cracks, bulges, or chafing.

If you observe any of these symptoms—especially a spongy pedal or a visible leak—do not drive the vehicle until the issue is safely resolved.

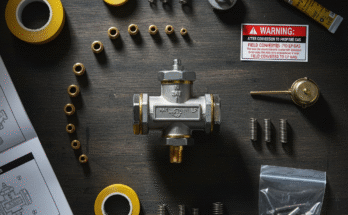

Anatomy of a Safe Brake Line Repair Kit

A safe “brake line repair kit” focuses on splicing in a new section of hard line or replacing an existing one entirely, always prioritizing the original line’s integrity.

The Essential Materials: Tubing and Fittings

The material choice is critical for a lasting repair:

- Brake Line Tubing:

- NiCopp (Copper-Nickel): Recommended for its exceptional corrosion resistance and ease of use. It is significantly more pliable than steel, making it easier to bend and flare, which minimizes common mistakes for the DIYer.

- PVF-Coated Steel: High-strength steel with a polyvinyl fluoride coating for rust protection. It is durable but less flexible than NiCopp.

- Standard Steel: Durable but difficult to work with and highly susceptible to rust in harsh environments.

- Brake Line Fittings (Nuts): These small, threaded connectors secure the line. They must precisely match your vehicle’s thread pitch and be compatible with the type of flare you create.

The Non-Negotiable Tools

A quality repair demands quality, specialized tools:

- Flaring Tool Kit: Absolutely essential for creating the perfect, high-pressure, leak-proof “flare” on the new tubing. An improper flare is a direct route to brake failure. A reliable double flaring tool is required for most common vehicles.

- Tubing Cutter: Necessary for making clean, perpendicular cuts, which is crucial for a successful flare.

- Tubing Bender and Straightener: Prevents kinking and ensures smooth, correct bends when routing the new line, maintaining proper pressure integrity.

- Unions/Connectors (Couplers): Used to securely join a new section of line to the existing, undamaged line.

DIY Repair: Pros, Cons, and Crucial Caveats

For those with mechanical competence, a brake line repair can offer substantial cost savings and component control.

Pros

- Significant Cost Savings

- Component Upgrade

- Corrosion Resistance

- Faster Turnaround

Cons & Caveats

- High-Risk Safety Component: A faulty connection can lead to total brake failure.

- Specialized Tools: High-quality flaring tools are mandatory.

- Technical Skill: Creating a perfect flare requires practice and precision.

- Risk of Imminent Failure: Replacing the entire line is often the safer, long-term solution.

The Critical Role of the Flare

The ability to create a flawless flare is the most important skill. The flare is what secures the line to the fitting, withstanding extreme pressure.

- Practice: Consistently produce perfect flares on spare tubing before working on the vehicle.

- Correct Type: Know your vehicle’s requirement: Double Flare (Inverted) is common in American/Japanese cars; Bubble Flare (ISO) is common in European cars. Using the wrong flare type will result in catastrophic failure.

The Forbidden “Quick Fix”: Compression Fittings

A critical warning: Never use a standard compression fitting on a high-pressure hydraulic brake line. They are not engineered to hold the pressure of a modern braking system and are widely considered an unsafe, temporary patch that invites sudden failure. Avoid them entirely.

When to Call the Professional

Even a skilled home mechanic should recognize when the job exceeds DIY capacity. Entrust the repair to a certified professional when:

- Long, Complex Runs: Lines running front-to-rear are labor-intensive, often requiring the fuel tank or exhaust system to be dropped for proper access.

- Multiple Failure Points: If severe corrosion is detected in several areas, a full, professional replacement of the line end-to-end is the safest course.

- ABS/Stability Control Systems: Modern vehicles with complex Anti-lock Braking System (ABS) require specialized diagnostic tools for proper bleeding, system cycling, and sensor reset after a line repair.

- Lack of Confidence: Because your life depends on your brakes, if you have any doubt about your ability to create a safe, pressure-tested connection, call an expert.

Final Word: Safety Over Savings

A brake line repair kit provides the tools for a quality, lasting repair, but it demands meticulous precision and respect for the physics of your braking system. By choosing superior materials like NiCopp and mastering the critical technique of flaring, the experienced DIYer can proceed with confidence. For everyone else, remember that no cost savings are worth compromising the safety and reliability of your vehicle’s most vital component. Always choose the path that guarantees a secure, leak-free, and safe stop every single time.