If you own a zero-turn or lawn tractor with a 46-inch mower deck—such as a Husqvarna RZ46i, RZ4623, or a compatible John Deere 46-inch model—you know it’s the workhorse of your yard. Unfortunately, after years of battling uneven terrain, rocks, and thick grass, those vital spinning components wear down. That tell-tale loud rumble, the uneven cut, or the smoke coming from your deck often signals that it’s time for a major overhaul.46i Deck Rebuild Kit

The good news? You don’t need to buy a whole new mower. A quality 46-inch deck rebuild kit is the perfect solution. It provides all the mechanical components you need to restore your deck to factory-new performance, often for a fraction of the cost of professional repair.

This comprehensive guide will walk you through everything you need to know: what’s in the kit, why you need it, how to choose the right one, and a step-by-step process for successful installation.

Why You Can’t Ignore Deck Failure

Before diving into the kit itself, let’s look at why rebuilding is so crucial. A failing mower deck isn’t just a minor annoyance; it’s a recipe for poor lawn health and even safety hazards.

The Symptoms of a Worn Deck

Your mower deck relies on precision. When parts wear out, the balance is gone. If you notice any of these signs, your spindles, pulleys, and belt are likely failing:

- Loud, Rattling Noise: This is typically the sound of failed spindle bearings. When the grease dries out or the bearing cage breaks, metal-on-metal friction creates a terrible grinding or loud rattling sound, especially when the blades are engaged.

- Vibration and Uneven Cut: Worn spindles or bent shafts cause the blades to wobble. Consequently, your mower leaves strips of high and low grass, creating an unsightly, uneven finish and often making the whole mower shake violently.

- Smoking or Burning Smell: This usually indicates a failing belt or seized pulley/spindle. The belt slips over a jammed pulley, creating intense heat and burning rubber. Furthermore, this friction drastically reduces power transfer, meaning your blades spin slowly, struggling to cut even thin grass.

Ignoring these issues won’t save you money. In fact, continued use with failing components places immense stress on the engine, the transmission, and the remaining good components, leading to much more expensive repairs down the road. 46i Deck Rebuild Kit

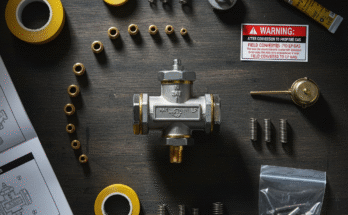

What’s Inside the 46-Inch Deck Rebuild Kit?

A quality 46-inch deck rebuild kit is a carefully curated package designed to replace all the most frequently failing mechanical parts of your deck. While the exact contents may vary slightly between manufacturers (Husqvarna, John Deere, aftermarket brands like 8TEN or Proven Part), the core components remain consistent.

1. Spindle Assemblies (The Core Component)

These are arguably the most critical parts in the kit. The spindles are the housing units that hold the bearings and the shaft that the blade bolts onto.

- Quantity: Typically (2) in a 46-inch two-blade deck kit, or (3) in some 46/47-inch John Deere kits.

- Function: Spindles transmit power from the pulley (via the belt) to the cutting blade. When the internal bearings fail, the spindle seizes up or vibrates violently.

- Key Feature: Look for spindles that include grease fittings (zerks). Therefore, you can perform routine lubrication, extending their lifespan far beyond cheaper, sealed units.

2. Mower Blades

Since you’re tearing down the deck, it’s the perfect time for new blades.

- Quantity: (2) blades for most 46-inch decks.

- Types: Kits usually include Standard Lift (general cutting) or Mulching Blades (shredding clippings finely). Conversely, some vendors offer kits with High-Lift blades for maximum bagging performance, so check your needs before buying.

3. Deck Belt

The drive belt is a high-wear item that transmits power from the engine’s clutch to the spindles and pulleys.

- Quantity: (1) main deck belt.

- Specification: The belt must match the exact length and profile (usually inch width) specified for your deck model (e.g., Husqvarna 539117245). Consequently, using an incorrect belt can cause slippage, excess heat, and premature failure.

4. Idler and Spindle Pulleys

These components guide the belt and maintain tension.

- Idler Pulleys: Kits often include (1-2) Idler Pulleys. These are static pulleys that guide the belt and may be flat or v-shaped.

- Spindle Pulleys: These mount directly on top of the spindle shafts and drive the blades. Kits usually contain (2) of these. In addition, ensure these pulleys have the correct internal star or hexagonal pattern to mate properly with your new spindle shafts.

Choosing the Right Kit: OEM vs. Aftermarket

Deciding between an Original Equipment Manufacturer (OEM) kit and an Aftermarket kit is the most important choice you’ll make, impacting both cost and longevity. 46i Deck Rebuild Kit

OEM Kits

- Pros: Guaranteed fitment and typically higher quality control. You know you’re getting the exact same specification as the parts that originally came on your machine.

- Cons: Significantly higher cost.

- Best For: Commercial users or those who demand the absolute best factory quality and don’t mind the premium price.

Aftermarket Kits

- Pros: Outstanding value. You can often buy a complete aftermarket kit for the price of just one OEM spindle. Many companies specialize in producing high-quality compatible parts (e.g., 8TEN or Caltric).

- Cons: Quality can vary dramatically. Therefore, always research the vendor and check customer feedback regarding bearing quality and belt durability. Look for kits with greasable spindles for better longevity.

- Best For: Homeowners, DIY mechanics, and anyone looking for a cost-effective solution that provides performance close to OEM.

The DIY Rebuild: A Step-by-Step Guide

Rebuilding your 46-inch deck is a job that most mechanically inclined homeowners can tackle in an afternoon. However, always prioritize safety and have the right tools ready.

Preparation and Safety Checklist

- Safety First: Disengage the mower deck, turn off the engine, remove the ignition key, and disconnect the spark plug wire (or battery) to prevent accidental starting.

- Access: Lower the deck fully, remove the tension springs and belts, and disconnect the lift arms. Slide the entire deck out from under the mower.

- Flip and Clean: Flip the deck over onto a clean, stable surface (like a workbench). Scrape off all built-up grass, dirt, and debris. This step is mandatory, because it makes working on the fasteners much easier.

- Tools: You’ll need a good set of sockets and wrenches, an impact gun (highly recommended for stubborn bolts), a torque wrench, penetrating oil (like WD-40 or PB Blaster), and a sturdy spindle wrench or block of wood to hold the blades still.

Step-by-Step Installation

1: Removing Old Components (Blades and Spindles)

- Blades: Using your spindle wrench, block, or a chunk of wood wedged against the deck, secure the blade. Remove the large bolt holding the blade in place. Consequently, this often requires significant force, which is why an impact gun is helpful.

- Spindles: Once the blade is off, look for the four (or three) bolts holding the spindle assembly to the deck shell. Apply penetrating oil to these bolts and let them soak for 15 minutes. Remove these bolts and lift the old spindle assembly off. 46i Deck Rebuild Kit

2: Replacing Idler Pulleys

- Locate the large idler pulleys (the ones that tension the belt). These are usually held on by one main bolt.

- Remove the old pulleys and replace them with the new ones from your kit. Furthermore, pay attention to any washers or spacers to ensure the new pulley sits at the correct height and angle. Tighten securely.

3: New Spindle Assemblies

- Place the new spindle assembly onto the deck shell, making sure the blade alignment holes are oriented correctly (they should be angled toward the next spindle).

- Insert the mounting bolts. Therefore, use anti-seize compound on the threads if you plan on future maintenance.

- Crucial Step: Tighten the spindle bolts to the manufacturer’s specified torque (consult your mower manual!). Overtightening can crush the spindle housing, and under-tightening can cause vibration.

4: Spindle Pulleys and New Belt

- Slide the new spindle pulleys onto the tops of the new spindle shafts. These usually key into the shaft with a star pattern.

- Route the new deck belt according to the diagram in your owner’s manual (or a photo you took during disassembly). Ensure it is properly seated in all the pulley grooves.

- Install the tensioner assembly (usually the idler arm), making sure the belt is taut.

5: Blades and Final Check

- Install the new blades, ensuring the cutting edge faces up (or the cup shape faces the deck).

- Secure the blade bolts, tightening them to the correct torque specification. However, avoid over-tightening, as this can stretch or snap the bolt, ruining your new spindle shaft.

- Flip the deck back over, reinstall it under the mower, and hook up the lift arms and the main engine PTO belt.

- Finally, re-attach the spark plug wire/battery cable.

Maintenance for Extended Life

A fresh rebuild kit gives your deck a second life, but smart maintenance will ensure that life lasts for years.

- Grease Regularly: If your new spindles have grease zerks, use them! Apply a high-quality lithium grease every 10-15 hours of use or at least once per season.

- Keep it Clean: Grass clippings and moisture accelerate rust and wear. Consequently, always hose down or scrape the underside of the deck after heavy use.

- Check Blade Torque: After the first five hours of use, check the blade bolts and spindle mounting bolts, as they can sometimes loosen slightly after initial use.

Click Here For More Information